The Secret to Smarter Inventory: Unlocking Cost Savings with EOQ

1. Introduction to Economic Order Quantity (EOQ)

Have you ever wondered how businesses decide how much stock to keep? That’s where Economic Order Quantity, or EOQ, comes into play. Think of EOQ as a smart tool that helps companies figure out the best amount of inventory to order. It’s like a balancing act, ensuring they have enough products to meet customer demand without overspending.

So, what’s the big deal about EOQ? Well, businesses face a tricky problem: they need to keep enough items on hand to satisfy customers, but they also want to avoid piling up too much stock, which can lead to wasted money and resources. EOQ helps solve this puzzle by providing a formula that calculates the most cost-effective quantity to order. This means businesses can minimize their storage costs and prevent the hassle of running out of popular products.

No matter the size of a business – whether it’s a tiny local shop or a huge corporation – using EOQ can make a huge difference. It helps streamline operations, save money, and keep customers happy by ensuring that the right products are always available. In short, EOQ is an essential strategy for any business looking to thrive in today’s competitive market.

2. The Importance of Effective Inventory Management

Effective inventory management is crucial for any business aiming for success. Imagine running a store where you have too much stock piled up – that’s called overstocking. It can lead to wasted money and resources, as products take up space and may even go out of date. On the flip side, if you don’t have enough products on hand – this is called understocking – you risk disappointing customers who come looking for what you sell, which can hurt your reputation and sales.

So, how does all this relate to cash flow and operational efficiency? Well, having the right amount of inventory helps businesses manage their cash flow better. If money is tied up in excess stock, it can limit the cash available for other important areas, like paying employees or investing in growth. Plus, when inventory is managed effectively, operations run smoother. Staff can spend less time dealing with stock issues and more time focusing on serving customers.

That’s where EOQ comes in! It’s a handy tool that helps businesses strike the perfect balance between overstocking and understocking. By using EOQ, companies can determine the optimal amount of inventory to order, ensuring they have what they need without wasting resources. In short, good inventory management is key to keeping a business healthy and thriving.

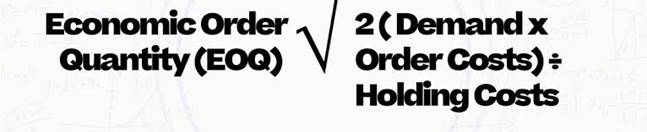

3. What is the Economic Order Quantity (EOQ) Formula?

Now let’s dive into the nuts and bolts of the Economic Order Quantity (EOQ) formula. At its core, EOQ is a mathematical equation that helps businesses calculate the ideal amount of inventory to order at one time. The formula looks like this:

Let’s break this down into bite-sized pieces.

– D represents the Annual Demand in units. This is how many products your business expects to sell in a year.

– S stands for the Ordering Cost per Order. This is the cost incurred every time you place an order, regardless of how many items you’re ordering.

– H is the Holding or Storage Cost per Unit per Year. This is how much it costs to keep one unit of inventory for a year, including things like storage space and insurance.

4. Why EOQ is Important for Inventory Management

Understanding Economic Order Quantity (EOQ) is super important for businesses, big or small. So, why should businesses care about EOQ? First off, EOQ helps find the perfect balance between two major costs: ordering costs and holding costs.

Ordering costs are the expenses that come every time a business places an order. This includes things like shipping fees, paperwork, and handling. On the other hand, holding costs are what it costs to keep products stored, like rent for storage space and insurance for the items. EOQ helps businesses figure out how much to order so they spend the least amount of money on both of these costs.

By using EOQ, companies can save money in a few big ways. For starters, it reduces overall inventory costs. This means businesses aren’t wasting money on too much stock sitting around, which can also lead to products going out of date or becoming damaged. Plus, EOQ helps prevent stockouts, which is when a business runs out of products. Running out can be a huge problem because it frustrates customers and can lead to lost sales.

Let’s look at how EOQ can help businesses of different sizes. A small business, like a local bakery, might find that using EOQ helps them order just enough flour, sugar, and other ingredients to meet customer demand without wasting money. A medium-sized company that sells gadgets can use EOQ to ensure they always have popular items in stock while avoiding too much unsold inventory. Finally, a large corporation might use EOQ to manage thousands of different products across multiple warehouses, ensuring they keep their operations running smoothly while saving big bucks.

In short, EOQ is a smart strategy that helps businesses save money, keep customers happy, and run more efficiently. When businesses take EOQ seriously, they can avoid cash flow problems and make better decisions about their inventory.

5. Step-by-Step Guide: How to Calculate EOQ

Calculating Economic Order Quantity (EOQ) might sound tricky, but it’s actually pretty simple when you break it down into steps. Here’s a straightforward guide to help you calculate EOQ for your business.

Step 1: Gather Your Information

You’ll need three key numbers:

– Annual Demand (D): How many units you expect to sell in a year. For example, let’s say you sell 1,200 t-shirts each year.

– Ordering Cost (S): The cost to place an order each time, regardless of the quantity. Let’s say this cost is $30.

– Holding Cost (H): The cost to store one unit for a year. Imagine it costs $2 to store each t-shirt for a year.

Step 2: Plug Your Numbers into the EOQ Formula

Now that you have your numbers, you can use the EOQ formula:

Plugging in your numbers:

– D = 1,200

– S = 30

– H = 2

So, you’d want to order about 190 t-shirts each time you place an order.

Step 3: Analyze the Results

This number tells you the best amount to order to minimize costs. But what if your numbers change? If your annual demand increases to 2,400 t-shirts, or if your ordering cost drops to $20, you would need to recalculate. Changing any of these numbers will affect your EOQ.

Step 4: Use Tools to Help

To make calculating EOQ easier, consider using spreadsheets like Excel. You can set up a simple formula, and whenever your numbers change, the spreadsheet will quickly give you the new EOQ. There are also software tools available specifically for inventory management that can calculate EOQ for you.

6. Key Benefits of Using the EOQ Formula

Using the Economic Order Quantity (EOQ) formula can bring a lot of positive changes to a business’s inventory management. One of the main advantages is that EOQ helps reduce overall inventory costs. By calculating the right amount to order, businesses can avoid spending too much on excess stock or wasting money on storage fees. This means more money can be used for other important areas of the business!

Another significant benefit is that EOQ helps prevent over-ordering or under-ordering stock. When businesses know exactly how much to order, they can avoid the pitfalls of having too much inventory sitting around (which can lead to spoilage or extra costs) or not having enough on hand (which can disappoint customers). This balance is key to maintaining customer satisfaction and a good reputation.

EOQ also plays a big role in helping businesses manage cash flow better. By optimizing stock levels, businesses can ensure that they are not tying up too much money in inventory. This way, they can have cash available for other needs, such as paying employees or investing in new projects.

Additionally, using EOQ leads to a more efficient use of storage space. When inventory is kept at optimal levels, businesses don’t have to rent extra space or deal with clutter in their storage areas. This organization can lead to faster retrieval times and smoother operations overall.

In the long run, the benefits of using EOQ extend to improved decision-making and better forecasting. When businesses consistently calculate EOQ, they gain valuable insights into their inventory patterns. This data helps them make informed decisions about future orders and anticipate changes in customer demand more accurately. All these factors come together to create a more streamlined, efficient, and profitable business operation.

7. Limitations of the EOQ Model

While the Economic Order Quantity (EOQ) model has many benefits, it’s important to understand that it also has some limitations. One major assumption of the EOQ model is that demand is constant. This means it assumes a steady number of units will be sold throughout the year, which isn’t always the case in real life. Demand can fluctuate due to trends, seasons, or unexpected events, making EOQ less effective in those situations.

Another assumption is that the costs associated with ordering and holding inventory are fixed. However, costs can change over time due to factors like supplier pricing, shipping fees, or changes in storage costs. If these costs vary significantly, the EOQ formula may not give accurate results.

The EOQ model also assumes that lead times (the time it takes to receive an order after it’s placed) are stable. In a fast-paced business environment, lead times can vary based on supply chain issues, supplier reliability, or other factors. This instability can lead to stockouts or overstocking if businesses rely solely on EOQ.

Certain types of businesses may find that EOQ isn’t suitable for them. For instance, companies with fluctuating demand – like those in fashion or tech – may need a more flexible approach. Similarly, fast-growing or seasonal businesses that experience sudden spikes in demand might not benefit from the fixed nature of the EOQ model. Lastly, companies that can take advantage of bulk discounts may prefer to buy larger quantities than what EOQ suggests.

For more dynamic environments, businesses might consider alternative models. For example, the Just-in-Time (JIT) model focuses on receiving goods only as they are needed, minimizing inventory costs. ABC analysis is another method that categorizes inventory into three groups based on value and turnover rate, allowing businesses to prioritize management efforts.

8. Real-Life Applications of EOQ

The Economic Order Quantity (EOQ) formula is not just a theoretical concept; it has practical applications across various industries. Let’s take a closer look at how different sectors use EOQ to improve their inventory management and streamline operations.

Retail is one of the sectors where EOQ shines. For instance, consider a small boutique that sells clothing. By using EOQ, the boutique can determine the optimal number of each clothing item to order. If the boutique finds that it sells 1,000 shirts annually, has an ordering cost of $40, and incurs a holding cost of $5 per shirt, using the EOQ formula helps them maintain just enough stock to meet customer demand without overstocking. This allows the boutique to reduce storage costs and avoid having to mark down unsold items at the end of the season.

In the manufacturing industry, EOQ plays a vital role in ensuring that production runs smoothly. For example, a company that manufactures electronic gadgets needs various components like resistors and capacitors. By calculating EOQ for each component, the manufacturer can keep production running without interruption while minimizing excess inventory. This is particularly important in manufacturing, where space is often limited, and carrying too much stock can be costly.

The healthcare sector also benefits significantly from EOQ. Hospitals and clinics often deal with medical supplies that have a limited shelf life, such as bandages, syringes, and medications. By applying EOQ, healthcare facilities can order just the right amount of supplies needed for patient care, ensuring they are always well-stocked without wasting money on expired products. For example, a hospital could analyze its annual usage of surgical gloves and determine the best order quantity to keep costs low while ensuring adequate supply.

Both small and large businesses can adapt EOQ to their inventory management strategies. A small local café might use EOQ to manage its stock of coffee beans and pastries, ensuring that fresh items are always available for customers while minimizing waste. Meanwhile, a large multinational company could apply EOQ across its global supply chain, managing thousands of products efficiently.

A real-world case study highlighting EOQ’s impact is Walmart. Known for its efficient inventory management, Walmart uses sophisticated data analysis, including EOQ principles, to keep inventory levels optimal across its stores. This strategy has led to improved inventory turnover rates and reduced carrying costs, allowing Walmart to maintain its reputation for low prices.

9. How EOQ Helps Prevent Stockouts and Overstocking

Managing inventory can be challenging for businesses, but using the Economic Order Quantity (EOQ) formula can help avoid two major problems: stockouts and overstocking.

A stockout happens when a business runs out of a product. This can lead to lost sales and unhappy customers. For example, if a customer wants to buy a popular item but finds it out of stock, they might go to a competitor instead. EOQ helps prevent stockouts by calculating the right amount of inventory to order based on how much customers are likely to buy. This way, businesses can have enough products available to meet customer demand.

On the other hand, overstocking occurs when a business orders too much inventory. This can lead to high holding costs, which include expenses for storing items, insurance, and the risk of items going unsold or becoming outdated. EOQ helps businesses avoid overstocking by determining the optimal order quantity. This means they can stock enough items to satisfy customers without wasting money on excess inventory.

The EOQ formula is crucial for keeping a good balance. It helps businesses understand their demand patterns and ordering costs, allowing them to plan ahead. For example, a small bookstore can use EOQ to decide how many copies of popular books to order based on sales trends. This ensures they have enough of the books customers want without ordering too many that might not sell.

10. Tools and Software for EOQ Calculation

Calculating Economic Order Quantity (EOQ) can be made much easier with the right tools and software. Here are some popular inventory management systems that can help:

1. QuickBooks: This well-known accounting software includes features for tracking inventory and calculating EOQ easily.

2. NetSuite: A comprehensive business management solution that provides advanced inventory control tools, including EOQ calculations for larger businesses.

3. Zoho Inventory: This software works well for small to medium-sized businesses and includes tools for managing stock levels and calculating EOQ.

4. Fishbowl Inventory: This inventory management system can work with QuickBooks and offers various tools for managing inventory and applying EOQ.

For small businesses that want free or low-cost options, consider these:

– Google Sheets or Excel: You can create a simple EOQ calculator using basic spreadsheet functions. Many free templates are available online to help you get started.

– inFlow Inventory: This software has a free version that helps small businesses manage their inventory, including EOQ calculations.

When choosing software, think about how complex your inventory needs are. If your business has a simple inventory system with just a few products, a basic spreadsheet or free tool might be enough. However, if you manage a larger inventory with many different products, investing in more advanced software like NetSuite or QuickBooks could save you time and make things easier.

11. EOQ for Fast-Growing Businesses: Adjusting the Formula

For businesses that are growing quickly, like startups or seasonal companies, using the Economic Order Quantity (EOQ) formula can be a bit tricky. Because these businesses often face changing demand and costs, it’s important to adjust the EOQ formula to keep inventory management effective.

When a business experiences fluctuating demand, it may need to modify the EOQ formula. For example, a startup that launches a new product may find that sales suddenly increase, meaning they need to order more inventory. In such cases, regularly updating the annual demand (D) in the EOQ calculation is essential to ensure they have enough stock to meet customer needs.

Similarly, if ordering costs change – perhaps due to a new supplier or increased shipping fees – businesses should adjust the EOQ formula accordingly. Keeping a close eye on these factors will help businesses avoid stockouts or excess inventory.

Businesses that might need to adjust their EOQ calculations frequently include seasonal businesses. For instance, a company that sells holiday decorations will experience a surge in demand leading up to the holiday season, requiring them to reevaluate their EOQ regularly. This flexibility is key to staying competitive.

Regularly reviewing EOQ calculations is crucial for any fast-growing business. Changes in the market, customer preferences, and operating costs can all impact how much inventory a business should order. By staying proactive and adjusting EOQ as needed, businesses can maintain optimal stock levels and support their growth effectively.

12. EOQ vs. Other Inventory Management Models

When it comes to managing inventory, the Economic Order Quantity (EOQ) model is just one option among several. Let’s compare EOQ to a few other common inventory management models to see how they stack up.

Just-in-Time (JIT) is a model that focuses on keeping minimal stock on hand and placing frequent orders. This approach reduces storage costs but requires precise demand forecasting. For businesses with unpredictable sales, JIT can lead to stockouts, making EOQ a better choice for maintaining balance between ordering and holding costs.

ABC Analysis is another method where inventory items are prioritized based on their importance or profitability. Items are classified into three categories: A (high value), B (moderate value), and C (low value). This method helps businesses focus their resources on the most valuable items. While EOQ determines how much to order, ABC Analysis helps identify what items need more attention. Many businesses find that using both methods together provides a comprehensive approach to inventory management.

Reorder Point (ROP) focuses on when to reorder inventory rather than how much to order. This model sets a specific level of inventory that triggers a reorder. ROP can work well for businesses that have consistent sales patterns. However, EOQ offers a more thorough understanding of the ideal order quantity, which can complement ROP by helping to decide how much to order when the reorder point is reached.

So, when should a business use EOQ over these other models? If a company has stable demand and wants to minimize costs, EOQ is a great choice. However, for businesses with fluctuating demand or those that require tight control over inventory levels, combining EOQ with JIT, ABC Analysis, or ROP could yield the best results.

13. Why EOQ is Essential for Efficient Inventory Management

In summary, the Economic Order Quantity (EOQ) formula is a powerful tool for businesses looking to optimize their inventory management. By calculating the ideal order quantity, businesses can significantly reduce costs associated with overstocking and stockouts. This balance not only helps maintain customer satisfaction but also improves overall operational efficiency.

Using EOQ allows businesses to better understand their inventory needs, which leads to smarter purchasing decisions and less wasted money on excess inventory. Whether you run a small boutique, a growing startup, or a large corporation, implementing EOQ can streamline your inventory processes and enhance your bottom line.

Now is the time to take action! If you haven’t already, start by calculating your own EOQ based on your business’s specific needs. You can even use various inventory management tools available today to help with this process. With EOQ in your inventory management strategy, you’ll be well on your way to a more efficient and cost-effective operation. Don’t wait – start optimizing your inventory today!