Smoother Transactions with Purchase Orders

Ever wondered if there’s a way to keep business orders from turning into a messy pile of forgotten emails and misplaced receipts? Enter the Purchase Order – or PO for short! Think of it as your official “receipt in advance” for big business buys. Just like ordering pizza with all your favorite toppings, you create a PO listing exactly what you want, so your supplier knows how to deliver (minus the pepperoni).

In this guide, we’re diving into everything you need to know about purchase orders, or POs: what they are, how they work, and why they’re the unsung heroes of smooth business transactions. We’ll break down the difference between PO invoices and non-PO invoices (yes, there’s a difference!), show you how to create a PO, and explain how they can help you stay organized, track spending, and avoid order mix-ups.

So, if you’re ready to bring some order to your orders, keep reading! By the end, you’ll know how to use purchase orders like a pro and streamline your purchasing process with ease.

1. What Is a Purchase Order?

A purchase order (often called a PO) is a formal document that kicks off a business transaction. It’s a little like sending a “shopping list” to your favorite store, but way more official! Created by the buyer and sent to the seller, a purchase order requests specific goods or services and spells out all the details – from item descriptions and quantities to agreed prices and delivery dates. Once accepted by the seller, the PO becomes a binding contract, setting clear terms for both parties.

So, what’s the big deal with POs? Purchase orders play a huge role in keeping business transactions organized and on track. Imagine if companies just made informal phone calls for orders; things would get chaotic fast! With a PO, both the buyer and seller have a clear, written record of what’s been ordered, making it easier to avoid miscommunications, ensure order accuracy, and track payments. When the goods or services arrive, the buyer can cross-reference them with the PO to confirm everything matches before issuing payment. POs are a safeguard, ensuring everyone is on the same page throughout the purchasing process.

Who uses purchase orders? Just about every industry where businesses buy goods or services in bulk. Retail, manufacturing, construction – you name it, they likely use POs. For example, a retail store might send a PO to a supplier requesting a certain number of clothing items for an upcoming season. In manufacturing, a company might issue a PO to a parts supplier to stock up on materials needed for production. By using POs, these businesses can track their orders, manage inventory, and keep their financial records in check.

2. What Is a P.O. Number?

A P.O. number, or purchase order number, is the unique code assigned to each purchase order. Think of it like a barcode for your order! This number becomes the order’s ID, helping both the buyer and seller manage and track it from start to finish. Imagine a busy office or warehouse without P.O. numbers – orders would get jumbled up, and keeping track of who ordered what (and when) would be nearly impossible.

So, what’s the importance of a P.O. number? When a buyer sends a PO to a supplier, they assign it a unique number that allows everyone involved to identify that specific order among others. As the order progresses – from request to shipment to delivery – the P.O. number serves as a reference that’s easy to look up. Both parties can check the P.O. number to confirm order details, track its status, and keep records accurate, helping avoid costly mistakes or order mix-ups.

How are P.O. numbers used? In most businesses, every department that handles the order will use the P.O. number, from accounting (to track payments) to inventory management (to ensure orders align with stock levels). For example, a warehouse worker can look up a P.O. number to check which items should be shipped, while the accounts department can reference it to confirm when and how much to pay for the received items. P.O. numbers simplify the purchasing process, creating an efficient system where everyone has easy access to essential order information.

3. How Do Purchase Orders and Invoices Work?

Purchase orders (POs) and invoices are two essential documents that keep business transactions running smoothly. They might seem similar, but they actually serve different purposes and work together to create a clear, organized buying and payment process.

Let’s start with the purchase order. The PO is created by the buyer and sent to the supplier to formally request specific goods or services. It includes details like product descriptions, quantities, prices, and delivery terms, along with a unique P.O. number for tracking. This document is the buyer’s way of saying, “Here’s exactly what I need, when I need it, and what I’m willing to pay.” Once the supplier accepts the PO, it becomes a binding contract.

After the goods or services are delivered, the supplier will send an invoice. Think of the invoice as the supplier’s bill – it outlines what was delivered, the final cost, and payment terms, and it references the P.O. number. This is where the two documents meet. The buyer can check the invoice against the original purchase order to make sure everything lines up. If the invoice matches the PO, the buyer knows they’re being charged correctly for the agreed items, quantities, and prices.

This verification process is often called invoice matching or “three-way matching” in accounting. The buyer will compare three things: the purchase order, the invoice, and the packing slip or delivery receipt (proof of what was actually received). If everything checks out, the buyer approves the invoice for payment. But if there are discrepancies – like unexpected charges or incorrect quantities – this process helps catch them early, so they can be resolved with the supplier before payment.

4. What Are PO Invoices and Non-PO Invoices?

In business transactions, invoices come in two main types: PO invoices and non-PO invoices. Each serves a distinct purpose and is processed differently, depending on whether a purchase order (PO) was created beforehand.

PO invoices are directly linked to a specific purchase order. This means that the buyer initially issued a PO with all the details of the goods or services they wanted, including quantities, prices, and delivery terms. When the supplier delivers these items, they issue a PO invoice that references this purchase order number. This way, the buyer can match the PO invoice to the original purchase order, ensuring everything aligns before processing the payment. PO invoices are standard in most business-to-business (B2B) transactions for goods, raw materials, or other regular purchases, as they streamline tracking and verification and help keep financial records accurate.

On the other hand, non-PO invoices aren’t tied to any specific purchase order. These invoices typically arise in situations where purchases are more ad hoc or don’t follow a set buying process. For instance, services like consulting, marketing, or utility bills may not require a purchase order. Instead, the supplier simply sends a non-PO invoice when the service is complete or the payment is due. Non-PO invoices are common in businesses where smaller, one-off, or non-standard purchases occur, and they’re often processed differently. Since there’s no PO to match, businesses may require additional approval steps to verify these expenses.

Processing each type of invoice varies slightly. For PO invoices, the accounts payable team can rely on three-way matching –comparing the PO, invoice, and delivery receipt – to verify that the invoice matches what was ordered and received. If everything aligns, the PO invoice gets approved, and payment moves forward smoothly. With non-PO invoices, since there’s no pre-existing PO, approval may require a manager’s sign-off or additional documentation, especially if the amount is significant. This helps prevent unauthorized or incorrect charges from slipping through.

5. How Do You Create a P.O. Number?

Creating a P.O. number is all about setting up a unique code that identifies each purchase order within a company’s purchasing system. This unique identifier simplifies tracking orders and ensures smooth communication between departments, suppliers, and the accounting team. Here’s a simple, step-by-step guide to creating a P.O. number, whether you’re using software or a manual system:

1. Choose a numbering format: Decide on a format that’s both logical and scalable. For example, many companies use a combination of letters and numbers, like “PO-2024-0001,” where “PO” represents the type of document, “2024” is the year, and “0001” is the order number. This way, each P.O. number is unique and provides a bit of information at a glance.

2. Start with a baseline: If it’s your first time generating P.O. numbers, start at a round number (e.g., 0001 or 1000). Each new purchase order will increment this number by one, helping to keep everything organized and sequential.

3. Automate with software: Accounting or inventory management software, such as QuickBooks, SAP, or Microsoft Dynamics, can automate P.O. number generation. Each time a purchase order is created, the software automatically assigns the next available number, saving time and reducing errors. This method is ideal for businesses handling high volumes of orders.

4. Track manually if needed: If your business is smaller or doesn’t have specialized software, you can track P.O. numbers manually. Use a spreadsheet or document to log each number as you create purchase orders, following your chosen numbering format. Just make sure to update it every time a new order is made to avoid duplication.

5. Keep it consistent: Ensure that your P.O. number format remains consistent across all orders. This consistency not only keeps things organized but also makes it easier for the accounting team and suppliers to identify and process orders correctly.

In short, creating a P.O. number is about setting up a system that fits your company’s needs. Using a clear, consistent numbering format (and, ideally, software) can make managing purchase orders a breeze, ensuring every order is easily trackable and well-documented.

6. What Information Should Be on a Purchase Order?

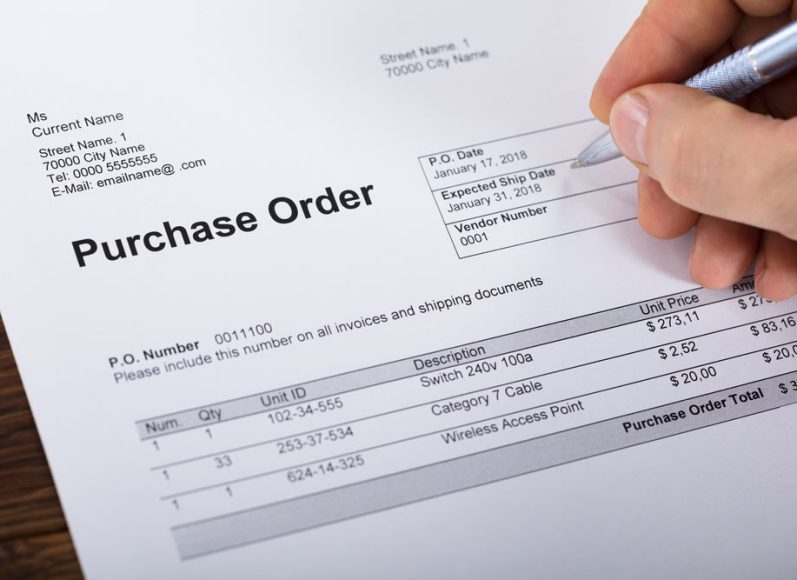

A well-organized purchase order (PO) includes several critical details that ensure both the buyer and supplier are aligned on the order. Each of these components helps prevent misunderstandings and simplifies the processing of orders. Here’s a breakdown of what should be included on every purchase order:

1. P.O. Number: This unique identifier tracks the order from creation to delivery. It’s referenced in all related documents and communications, helping everyone involved easily identify the order.

2. Buyer’s Details: Include the buyer’s name, company name, contact information, and billing address. This makes it clear who’s placing the order and where payment information should be sent.

3. Supplier’s Details: Add the supplier’s name, contact information, and shipping address, if different from the billing address. Having both sets of details allows for straightforward communication and proper order routing.

4. Description of Items or Services: List each item or service requested in the order, with specific descriptions. If it’s a product, include details like model numbers, sizes, or any special specifications. This helps the supplier know exactly what’s expected.

5. Quantity and Price: Clearly state the quantity and agreed price for each item or service. This section establishes the total order value and ensures both parties are on the same page regarding costs.

6. Terms and Conditions: Include any specific terms, such as payment terms (e.g., Net 30) or penalties for late delivery. Terms and conditions clarify expectations and set ground rules for the transaction.

7. Delivery Details: Mention the delivery date, method, and location. This ensures that both the buyer and supplier are clear on when and where the items should arrive, minimizing delivery errors.

Including all of these components on a purchase order ensures that everyone involved has the information they need for smooth processing, accurate deliveries, and timely payments. This attention to detail reduces errors, improves tracking, and keeps both buyers and suppliers aligned from the start.

7. Where to Include a P.O. Number on an Invoice

When creating an invoice, placing the P.O. number in a clear, visible spot is essential for accurate and efficient processing. The P.O. number typically goes at the top of the invoice or in the “reference” or “order number” section, which makes it easy for the recipient to find and match the invoice to the corresponding purchase order.

Including the P.O. number is more than just a formality; it’s a critical part of ensuring that your invoice is processed quickly and correctly. The accounts payable team will use the P.O. number to verify that the charges on the invoice match the original terms and quantities on the purchase order, helping avoid delays and disputes. If there’s no P.O. number or if it’s misplaced, the payment process can slow down, leading to follow-ups, manual checks, or even rejected invoices.

8. Importance of a Purchase Order Number

A purchase order (P.O.) number isn’t just a random code; it’s a powerful tool that plays a vital role in business transactions. The P.O. number is the unique identifier that connects every aspect of a purchase, making it essential for order tracking, inventory management, and financial record-keeping.

With a P.O. number, businesses can effortlessly track an order’s journey from the initial request to final payment. It provides an audit trail that’s invaluable during reconciliations, enabling teams to verify every detail in the purchasing process. Whether it’s matching invoices to orders or reviewing past purchases, a P.O. number provides a streamlined method for confirming that everything checks out.

For both buyers and suppliers, the P.O. number improves communication and reduces errors. When both parties refer to the same P.O. number, there’s no confusion about which order they’re discussing. This shared reference helps avoid costly mistakes, such as duplicate payments or unfulfilled orders, and minimizes time spent on back-and-forth communication.

9. P.O. Number Examples

A P.O. number can look different across industries, but its purpose remains the same: creating a unique identifier for every order. Here are some sample formats that illustrate how companies in various sectors might structure their P.O. numbers:

1. Retail: A retail store may use a format like PO-2024-0010, where “PO” identifies it as a purchase order, “2024” represents the year, and “0010” is the sequential order number. This format helps stores track purchases throughout the year with a unique number for each order.

2. Manufacturing: In manufacturing, the format might be more complex. For example, PO-MFG-24-1005, where “MFG” denotes the department (manufacturing), “24” is the year, and “1005” is the specific order number. This kind of structure aids in organizing orders by department.

3. Service-Based Industry: Service providers often include the client or project identifier. For instance, PO-C1234-07/24, where “C1234” refers to the client number and “07/24” is the date of order creation. This setup helps service-based businesses connect P.O. numbers to specific clients for easy tracking.

Each company may tailor its P.O. numbering system to suit its operational needs, with some numbering by date or department. Whichever structure is used, a logical and consistent format is key for streamlined order management and easy cross-referencing.

10. Frequently Asked Questions (FAQ)

Here are answers to some of the most commonly asked questions about purchase orders (POs) and P.O. numbers, helping to clear up potential misunderstandings and provide insight into effective usage.

Q1: Can a purchase order be canceled?

Yes, a purchase order can be canceled, but only under specific conditions. Usually, this happens when both the buyer and seller agree, and it typically occurs before the order is fulfilled. However, once items have shipped or services are in progress, canceling may involve penalties or fees, depending on the terms agreed upon in the P.O.

Q2: How does a P.O. number help with accounting?

A P.O. number is invaluable for accounting because it provides a clear trail for tracking each order from request to payment. It simplifies the matching process between invoices and orders, reducing errors, aiding in audit trails, and improving inventory management. Essentially, P.O. numbers ensure every transaction has a unique identifier, making reconciliation easier and more accurate.

Q3: Is a purchase order required for every purchase?

Not always. Smaller purchases or one-time orders may not need a purchase order, particularly if a formal agreement is not necessary. However, for larger transactions, repetitive orders, or when working with new suppliers, a P.O. is typically beneficial for clarity and accountability.

Q4: What happens if an invoice doesn’t have a P.O. number?

An invoice without a P.O. number may face delays in processing, as the accounts team relies on it to match invoices to the corresponding orders. Without it, there’s often confusion about what the invoice is for, leading to manual checks or even rejection of the invoice until the correct P.O. is provided.

Conclusion

In this article, we’ve explored the essentials of purchase orders (POs) and why P.O. numbers are so valuable in business transactions. P.O.s serve as formal requests for goods or services, providing a structured, trackable record from purchase to payment. We also discussed how P.O.s and invoices work hand-in-hand, with P.O. numbers playing a crucial role in organizing orders, reducing errors, and enhancing communication between buyers and suppliers.

For businesses aiming to improve their purchasing processes, incorporating P.O.s can lead to more efficient operations and financial clarity. By using dedicated invoicing software like Vantazo or other tools, managing P.O.s and invoices becomes even simpler and more efficient.